Pall Laboratory

Laboratory Filtration Solutions

Pall Laboratory is a global supplier of filtration, separation and sample preparation products for life science research and discovery, microbiology, environmental, analytical QC and cannabis applications. We maintain close ties with scientists, researchers and laboratory technicians worldwide to ensure our solutions offer accurate results, scalability, innovation, cost savings and easy-to-use operation. We are proud to have application specialists to support labs around the world, whether they are in private industry, academia or in the field. Our vast product portfolio and technical know-how helps us deliver products that truly make a difference, from field to lab. We are proud to offer superior filtration, separation and sample prep products to help advance science. Pall technologies touch people’s lives every day around the globe.

Innovative and Time-Saving Life Science Research Products

Streamline sample prep, ensure sterility and expedite analysis in life science research laboratory workflows.

Drug Development Research

To reduce drug discovery and development costs, there is pressure on life science researchers to rapidly move through the early stages of biotherapeutic discovery and biotherapeutic candidate selection. Key to driving efficiency is to quickly generate and select clonal cell lines that deliver high concentrations of quality recombinant protein, while screening out clone candidates that may fail in process scale-up as early as possible.

At Pall, we offer laboratory solutions to support researchers throughout the cell line development and clone selection process. High-performance proprietary membranes and innovative centrifugal devices address the challenges of DNA/RNA and protein sample preparation. Our high-tech filtration systems are designed to maintain sterility while streamlining harvest, clarification, and purification of cell culture products for analysis; reducing the risk of lost batches or the frustration and cost of inconsistent results due to contamination.

DNA & RNA Purification

The advent of next generation sequencing techniques has enabled collection of unprecedented amounts of sequencing data in short spans of time. This has greatly contributed to our understanding of genomic and gene structure across many species and has also allowed us to gain much information about candidate genes for genetic disorders, cancer-causing somatic mutations and misexpression due to epigenetic changes.

Protein Sample Preparation & Detection

Filtration, analysis and purification in preparing and detecting proteins presents tremendous challenges. From the discovery and development stages of new drugs, through to production and delivery of therapies, Pall Life Sciences provides dependable, high-performance products that expedite and simplify your processes. We have committed ourselves to providing many sample preparation and detection tools used in basic research and proteomics.

Sterile Filtration & Clarification

Reduce filtration time, increase throughput, reduce the need for multiple filter changes and save in overall filtration costs. We manufacture membranes that are used to sterilise liquid reagents, remove particulate contamination and clarify solutions prior to further processing. These products are optimised for biological, pharmaceutical and sterilising filtration requirements and exhibit superior performance compared to competitive filter devices.

Tangential Flow Filtration

Ultrafiltration preserves biological activity and saves time - protein purification technology has progressed from methods as diverse as chemical precipitation for sample concentration or dialysis for buffer exchange towards pressure-driven purification cross-flow systems utilising ultrafiltration membranes. Ultrafiltration (UF) techniques rely on the use of polymeric membranes with highly defined pore sizes to separate molecules according to size. Simply.

Quality Control in Laboratories

Increase column life and produce consistent, reliable results.

Reliable Results & Proven Performance

Quality Control Laboratories play a crucial role in identifying contamination and product issues before final release. The data generated by these QC labs helps guide critical decisions. The reliability of these results are demonstrated by Pall’s proven performance analysing samples from 150mL to less than 25µL.

Protect What Really Matters with Pall Laboratory Syringe Filter Technology

Syringe filters perform sample clean-up and preparation, ensuring the purest samples are analysed in liquid chromatography, mass spectrometry and ion chromatography applications. Reliable results depend upon accurate data, achieved by the low extractables and high particulate retention of our syringe filters.

Our High-Quality Laboratory Filters Meet the Unique Requirements of Every Lab We Serve

We continue to revolutionise the industry with new products and solutions to meet your laboratory’s ever-changing needs. We have a wide variety of analytical QC membranes including our new water-wettable polytetrafluoroethylene (the next generation in universal membrane filtration - see below), along with our nylon, PVDF, hydrophobic PTFE membranes and more.

- HPLC & UHPLC sample preparation

- LCMS sample preparation

- IC sample preparation

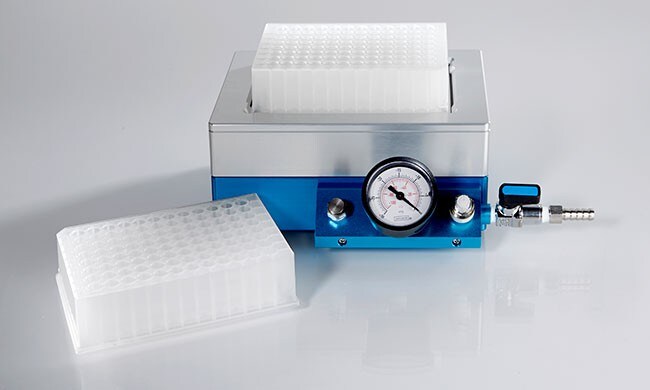

- High throughput sample preparation

- Mobile phase filtration

Featured New Products

The Pall Laboratory wwPTFE Membrane:

Our newest wwPTFE membrane comes in a variety of sizes to accommodate sample volumes from 25µL up to 150mL. Providing your laboratory with the ability to process single samples with the new Pall Laboratory Acrodisc One™ syringe filter, small volumes with the Nanosep™ spin device or up to ninety-six samples with the Acroprep™ Advance filter plate.

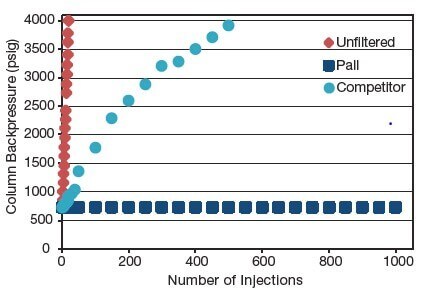

- Extend column life up to 52 times

- Reduce contamination with up to 24% less filter extractables than the competition

- Process single samples or up to ninety-six samples at once

- Simplify your sample preparation, saving time and money

Effects of filters on HPLC column life following injections of unfiltered and filtered 0.05% latex sphere suspensions. With unfiltered samples, the column failed due to plugging after 19 injections. Samples passed through competitor filters plugged the columns after 500 injections. No increase in backpressure was observed after 1000 injections of samples filtered with Pall Acrodisc One syringe filters.

Effective Product Quality Monitoring

Rapid microbiology and prep products from Pall speed up the time it takes to collect a sample, analyse it and produce test results.

The accurate, reliable detection and identification of microorganisms is critical to public safety and industrial economics. As we become more aware of the presence and variety of the organisms that share the world we live in, we realise the importance of knowing how to detect and control them.

We excel as a leader in the development and manufacture of products to detect and control these microorganisms. Our products comply with international testing methods, are supported by technical literature and carry certifications of quality. You can be confident that our affordable, easy-to-use products will meet the high quality standards you require.

Culturing sensitive organisms can be difficult and identification is critical for process control and public safety. Analysis membranes must be manufactured to the highest standards for accurate microbial growth and recovery. Our mixed cellulose ester GN Metricel™ membrane has set the standard worldwide for meeting stringent microbial regulations. Supor™ and Metricel Black membranes provide additional benefits that range from low drug and protein binding characteristics to background contrast for ease in counting colonies. These membranes provide uniform and consistent growth of organisms.

We also offer the widest selection of disposable filter funnels for microbiological analysis, offering unique design features that give these products a reputation for quality and ease of use.

MicroFunnel™ filter funnels make analysis easy. Design permits a simple squeeze separation of funnel from the base to access the membrane. Funnels attach directly to standard laboratory manifolds and volume graduations are clearly marked to make it easy to measure your sample volume. Each unit is individually bagged, gamma-irradiated and labelled for added assurance of lot traceability.

Finally, we offer a full line of microbiological ampoule media, unique membrane dispensers, pumps and accessories such as petri dishes and stainless steel forceps to simplify your microbial analysis procedures.

Cannabis Sample Preparation

For R&D, process monitoring and final product release testing.

Cannabis Sample Preparation Products from Pall Laboratory

Filtration during sample preparation helps facilitate cannabis testing including cannabinoids, potency, pesticides and terpenes, as well as yeast, mould and bacterial contamination. Pall’s wide variety of sample preparation products simplify and streamline cannabis analysis, enabling fast release to market through reliable QC data.

- Accurate and reliable results for potency, pesticides and terpene analyses with the Acrodisc™ syringe filter

- Streamline nucleic acid purification processes for PCR workflows including yeast and mould contamination and plant strain determination with Pall’s nucleic acid binding products

- Perform sensitive membrane filtration testing for microbial contamination using Pall’s MicroFunnel™ filter funnels

Pall Laboratory’s wide range of filtration products provide a complete solution to your cannabis sample prep needs.

Cannabis: R&D to Final Product in Three Steps

1) Research and Product Development

To develop a safe product for customers, the researcher must fully characterise the cannabis plant and all materials used in the development process including plant strains, terpenes and potency.

2) Incoming Materials and Process Monitoring

Incoming raw materials must be tested for pesticide residue, metals, bacterial, yeast and mould contamination. Testing is conducted during the manufacturing process to ensure safety and consistent yield.

3) Final Product Release Testing

Final products must be safe for human consumption and accurately reflect labelling claims. Final products must be tested for a range of contaminants including pesticides, metals, potency and microbial contamination.

Pall Corporation does not support, encourage or promote the use of its products or services in connection with any illegal use, cultivation or trade of cannabis or cannabis products. Pall products are intended to be used for cannabis-related purposes only in compliance with all applicable laws in a manner that promotes public safety and/or in connection with any lawful and approved scientific or research activities.

COVID-19 Has Impacted All of Us

We are your partner for all your filtration needs for COVID research.

Our laboratory products are helping in the fight against the Coronavirus (COVID-19) by assisting researchers around the globe in COVID-19 related workflows, from enabling detection of the virus to development of a vaccine. Our filtration products ensure reliable and consistent results for workflows such as:

- Sterile filtration of media, kits and reagents

- Viral protein concentration

- QC testing of drug candidates

- RNA extraction

- N95 performance testing

- Wastewater surveillance

- Conjugate viral proteins

- Viral collection of COVID-19 in air

We have a complete range of filtration products for all size requirements such as syringe filters, centrifugal devices, filter microplates, capsules, air/gas filters, vacuum devices, membrane discs, filter holders and more. We also have a team that can offer expert guidance based on individual application needs to match the best filtrations products for each application. Please inquire about how we can help you with your filtration, separation, and sample preparation needs.

Mapping Out Your Success

Fast processing with efficient removal of particulates.

The advent of next-generation sequencing techniques has enabled collection of unprecedented amounts of sequencing data in short spans of time. This has greatly contributed to our understanding of genomic and gene structure across many species and has also allowed us to gain much information about candidate genes for genetic disorders, cancer causing somatic mutations and misexpression due to epigenetic changes. Validation of candidate genes can take place by genetically engineered disease models created in mammalian cell culture or whole animal models. Many of the workflows involved in these studies are now carried out using high-throughput routines facilitated by multiwell DNA binding filter plates that allow larger numbers of genomic DNA samples to be obtained in parallel.

Prepared for Success with our Protein Sample Preparation

Advanced filtration, analysis and purification products for protein preparation and detection.

Reliable sample preparation and fractionation processes are key to the success of proteomic research. Effective steps can facilitate the discovery of life-saving and life-enhancing diagnostic and pharmaceutical products. Ineffective steps can lead to loss of valuable samples and time. We manufacture membranes and chromatography resins that exhibit high resolution and binding capacities with low non-specific binding for the purification and concentration of proteins. These media are available in devices that use fast, gentle methods and minimise handling to protect samples.

As samples get smaller and more numerous, the need for novel methods to purify proteins and improve assays has led Pall to develop a broad line of multiwell filter plates that target specific application challenges. AcroPrep™ Advance filter plates are designed to provide superior performance in a multitude of sample prep and screening applications. These multiwell filter plates have been optimised to support the stringent requirements of high throughput applications.

The sealing mechanism used in the AcroPrep Advance filter plate individually seals each well to help prevent cross-talk or cross-contamination of samples. The advanced fluid director on the bottom of the plate also minimises cross-contamination of the filtrate during processing.

Our ultrafiltration centrifugal devices simplify many common protein handling procedures. These devices provide efficient concentration and salt removal of samples from 50μL to 60mL in just minutes. Choose from membranes that have been developed to assure low nonspecific biomolecule binding and provide consistent, high recovery of target molecules. Ultrafiltration reduces the amount of handling that can cause damage to samples, leaving concentrated samples ready for direct incorporation into downstream applications at critical stages in the discovery process.

We also offer chromatography products to facilitate research needs, scale-up and polishing. Our chromatography solutions are available in resin or membrane formats to support your specific application. Choose from our extensive portfolio of media including flat sheet membrane, bulk resin and media incorporated into specific product housings.

Our Mustang™ membranes are recommended in chromatography applications when there is a need to purify large molecules or in situations where faster flow is required. Membrane chromatography is extremely economical because flow rates are significantly faster than traditional resin chromatography, decreasing processing time and increasing throughput. Pall’s Mustang membranes possess large convective pores and have dynamic binding capacities that are relatively insensitive to the effects of high flow rates, even for large molecules such as plasmids and viruses.

For protein characterisation, the use of membrane technology is ideal for obtaining detailed structural information. Pall offers an impressive range of membranes compatible with all common protein detection procedures. Our membranes feature superior binding capacities and extremely low background to facilitate the transfer and retention of rare and low-abundant proteins for detection and further characterisation.

Our strict quality manufacturing specifications ensure consistent, precise membrane performance from lot-to-lot and blot-to-blot. Our membranes set industry standards for reproducible results, durability and high signal-to-noise ratios. Choose from a range of commonly used formats including rolls, discs, sheets or custom cuts. We also offer a protocol support, such as the desalting column protocol.

Maximise Your Investment with Our Sterile Filtration and Clarification Portfolio

Minimise time to market and maximise all phases of development.

Laboratory sterile filtration and clarification techniques are critical in reducing potential contamination. We provide effective filtration sterilisation and clarification solutions for global laboratory industries.

Pall Laboratory filters reduce filtration time, increase throughput, reduce the need for multiple filter changes and save in overall filtration costs. We manufacture membranes that are used to sterilise liquid reagents, remove particulate contamination and clarify solutions prior to further processing. These products are optimised for biological, pharmaceutical and sterilising filtration requirements and exhibit superior performance compared to competitive filter devices. Many of these products are scalable and feature identical membranes used in GMP scale manufacturing filters offered by Pall Biotech.

All too frequently, days, weeks or, in the worst case, even months of cell culture work can be lost when bacterial, fungal or yeast contaminants are unknowingly introduced. Unfortunately, the same nutrient media that is used to grow cell cultures is often ideal for promoting the growth of these contaminants, which can quickly ruin your cultures. While there is no substitute for aseptic technique, sterilisation of liquids used during cell culture assures you that media and reagents are not a source of contamination. Heat sterilisation (autoclaving) is not an option for many liquids as autoclaving may destroy critical cell culture media components and biomolecules needed for normal cell growth. Sterile filtration, therefore, is the method of choice for sterilising cell culture media and additives. Filters capable of ambient sterilisation are also useful for the general clarification and purification of cellular broths and lysates as a means to enhance the recovery of target biomolecules.

We manufacture membranes that are used to sterilise liquid reagents, remove particulate contamination and clarify solutions prior to further processing. These products are optimised for biological, pharmaceutical and sterilising filtration requirements.

Whether you are preparing small volumes of reagents, individual bottles of buffers or media, or developing pharmaceutical processes, we have the products to optimise your sterile filtration applications. We can help you:

- Maximise product recovery

- Reduce filtration time

- Increase throughput

- Reduce the need for multiple filter changes

- Save in overall filtration costs

At Pall, quality and ease of use are engineered into every device. We manufacture our own membranes to ensure consistent performance from lot-to-lot. Examples of our stringent quality specifications include:

- Sterilisation by gamma irradiation – Products with Supor™ (PES), Fluorodyne™ II (PVDF) and Versapor™ (acrylic copolymer) membranes are pre-sterilised by gamma irradiation to eliminate potential cytotoxic residuals associated with EtO sterilisation. These pre-sterilised devices are individually packaged for convenience

- Biological safety – Passes United States Pharmacopeia (USP) Biological Reactivity Test, In Vivo <88>

- Non-pyrogenic – Products are tested for bacterial endotoxin using the Limulus Amoebocyte Lysate (LAL) test to ensure safety

- Low extractables – Products are optimised to reduce extractables, ensuring that unwanted materials are not introduced into filtered liquids

We offer a range of different devices to match your filtration requirements, throughput and volumes:

Sterile Syringe Filters

Acrodisc™ sterile syringe filters rapidly filter small volume samples and are available with diameters of 13, 25, 32, or 37mm. The Acrodisc sterile syringe filters are available with Supor (PES sterile filter) membranes featuring both a large EFA and PF (preflter) to maximise throughput and flow rate for sterile filtration and clarification requirements.

Bottle-Top Vacuum Filters

The sterile VacuCap™ and VacuCap PF (preflter) bottle-top filter was engineered for media preparation for cell culture applications. VacuCap PF devices, designed with a built-in prefilter, increase throughput performance with serum-containing media or other viscous solutions.

Capsules

AcroPak™ filter capsules are suited for sterile capsule filtration and prefiltration applications. Capsules are available with a variety of membranes to sterilise liquid reagents, remove particulate contamination and clarify solutions prior to further processing. AcroPak capsule filters are available with a Supor (PES) membrane featuring both a large EFA and PF (prefilter) to maximise throughput and flow rate.

Membranes

Membranes are used to sterilise liquid reagents, remove particulate contamination, and clarify solutions prior to further processing. These products are optimised for biological, pharmaceutical and sterilising filtration requirements.

Separation and Purification using Ultrafiltration

Accelerating and simplifying bioprocessing.

Ultrafiltration preserves biological activity and saves time: protein purification technology has progressed from methods as diverse as chemical precipitation for sample concentration or dialysis for buffer exchange, towards pressure-driven purification cross-flow systems utilising ultrafiltration membranes. Ultrafiltration (UF) techniques rely on the use of polymeric membranes with highly defined pore sizes to separate molecules according to size. Simply put, UF procedures rely on the use of fluid pressure to drive the migration of the smaller molecules through a UF membrane with the simultaneous retention of larger molecules.

While chemical precipitation can be used to concentrate a protein sample, separation with ultrafiltration is based on mechanical rather than chemical interactions, allowing a researcher to perform sample concentration without the addition of denaturing solvents or salts. Buffer exchange using dialysis technologies uses large volumes of buffer and since the only force acting upon the solution is diffusion, the process can take several days. Pre-assembled and simple-to-use ultrafiltration devices can rapidly perform either concentration or buffer exchange procedures without the extensive handling required for many other techniques.

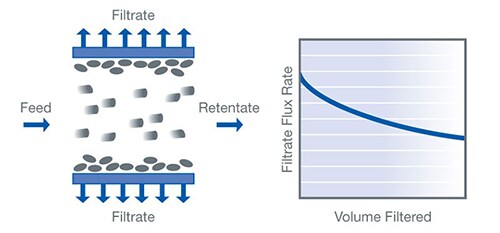

Ultrafiltration can be performed in one of two operational modes: Direct Flow Filtration (DFF) or Tangential Flow Filtration (TFF). DFF works well for small volumes (up to 30mL) using centrifugal devices; however, DFF technologies can fall prey to problems with membrane fouling. To reduce the formation of a gel layer, cross-flow can be generated on the upstream side of the membrane using a floating stir bar configuration (stirred cell) or by creating a controlled laminar flow. While stirred cell operations tend to improve UF performance, they are still limited in achieving their optimal performance since the velocity and subsequent level of agitation is dependent on the sweep of the bar that varies along the radius of the sweep.

What is Tangential Flow Filtration? (TFF)

Tangential Flow Filtration (TFF) is a rapid and efficient method for separation and purification of biomolecules. It can be applied to a wide range of biological applications such as immunology, protein chemistry, molecular biology, biochemistry, and microbiology. TFF can be used to concentrate and desalt sample solutions ranging in volume from 10mL to thousands of litres. It can be used to fractionate large from small biomolecules, harvest cell suspensions, and clarify fermentation broths and cell lysates.

Why Use Tangential Flow Filtration?

- Easy to set up and use – Simply connect the TFF device to a pump and pressure gauge(s) with tubing and a few fittings, add your sample to the reservoir, and begin filtration.

- Fast and efficient – It is easier to set up and much faster than dialysis. Higher concentrations can be achieved in less time than when using centrifugal devices or stirred cells.

- Perform two steps with one system – Concentrate and diafilter a sample on the same system, saving time and avoiding product loss.

- Can be scaled up or scaled down – Materials of construction and cassette pathlength allow conditions established during pilot-scale trials to be applied to process scale applications. TFF devices that can process sample volumes as small as 10mL or as large as thousands of litres are available.

- Economical – TFF devices and cassettes can be cleaned and reused, or disposed of after single use. A simple integrity test can be performed to confirm that membrane and seals are intact.

Consider the Biomolecule of Interest

Your biomolecule of interest, or product, can be retained and separated from the low molecular weight contaminants, or it can be passed and purified from higher molecular weight contaminants and particles.

In general, a membrane with a molecular weight cut-off (MWCO) should be selected that is three to six times smaller than the molecular weight of the protein to be retained. Other factors can also impact the selection of the appropriate MWCO. For example, if flow rate (or processing time) is a major consideration, selection of a membrane with an MWCO toward the lower end of this range (3x) will yield higher flow rates. If recovery is the primary concern, selection of a tighter membrane (6x) will yield maximum recovery (with a slower flow rate). These values should be used as a general guide, as solute retention and selectivity can vary depending on many factors, such as transmembrane pressure, molecular shape or structure, solute concentration, presence of other solutes, and ionic conditions.

Our membranes are highly selective and typically achieve recoveries in the range of 95 to 99%. The narrow pore size distribution of these membranes results in minimal molecule retention of molecular weights below the MWCO of the membrane.

Consider Fluid Characteristics

Sample concentration and viscosity determine the type of channel that is required for the process run. Our lab scale TFF devices are available in screen or suspended screen configurations. Typically, screen channel configurations are used for clarified, dilute solutions free of particulate or aggregates. Suspended screen channel TFF cassettes provide better performance with highly viscous or particulate-laden solutions.

Consider the Sample Volume and Processing Time

Choosing the appropriate cassette or device size depends on the total sample volume, the required process time, and the desired final sample volume.

Our Minimate™ system works with Minimate capsules to easily process sample volumes up to 1000mL. For process development and scale-up applications, Pall Life Sciences offers an extensive line of TFF holders and cassettes. With these products, a complete TFF system for full production can be optimised using the volumes typically generated in the development or discovery lab.

Key Applications of TFF

The primary applications of TFF are concentration, diafiltration (desalting and buffer exchange), and fractionation of large from small biomolecules. In addition, it can be used for clarification and removal of cells, as well as cellular debris from fermentation or cell culture broths.

Concentration

Concentration is a simple process that involves removing fluid from a solution while retaining the solute molecules. The concentration of the solute increases in direct proportion to the decrease in solution volume (i.e., halving the volume effectively doubles the concentration). To concentrate a sample, choose an ultrafiltration (UF) membrane with an MWCO that is substantially lower than the molecular weight of the molecules to be retained. This is important in order to assure complete retention and high recovery of the target molecule.

Diafiltration

Diafiltration is the fractionation process that washes smaller molecules through a membrane and leaves larger molecules in the retentate without ultimately changing concentration. It can also be used to remove salts or exchange buffers. It can remove ethanol or other small solvents or additives.

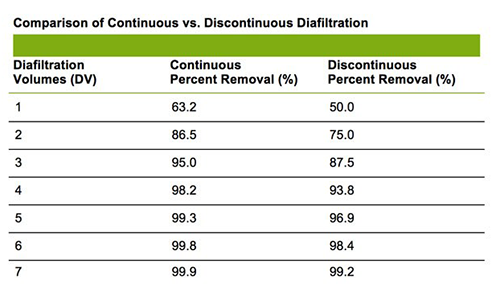

There are several ways to perform diafiltration. In continuous diafiltration, the diafiltration solution (water or buffer) is added to the sample feed reservoir at the same rate as filtrate is generated. In this way, the volume in the sample reservoir remains constant, but the small molecules (e.g., salts) that can freely permeate through the membrane are washed away. Using salt removal as an example, each additional diafiltration volume (DV) reduces the salt concentration further. (Adding a volume of water or buffer to the feed reservoir equal to the volume of product in the system, then concentrating back to the starting volume constitutes one diafiltration volume. For example, if you have a 500mL sample to start, 1 DV = 500mL.) Using 5 DV will reduce the ionic strength by ~99% with continuous diafiltration.

In discontinuous diafiltration, the solution is first diluted and then concentrated back to the starting volume. This process is then repeated until the required concentration of small molecules (e.g., salts) remaining in the reservoir is reached. Each additional DV reduces the salt concentration further. Using 5 DV will reduce the ionic strength by ~96% with discontinuous diafiltration. Continuous diafiltration requires less filtrate volume to achieve the same degree of salt reduction as discontinuous diafiltration, as illustrated in the table below. By first concentrating a sample, the amount of diafiltration solution required to achieve a specified ionic strength can be substantially reduced. To reduce the ionic strength of a 1 litre sample by 96% using discontinuous diafiltration requires 5 DV or, in this case, 5 litres. If the sample is first concentrated tenfold to 100mL, then 5 DV is now only 500mL. This represents a substantial saving in buffer and time.

Protect your investment

Maintain the sterility of the interior environment and protect the atmosphere from contaminants within the vessel.

Venting and gas filtration is an essential part of laboratory operation. Venting may be as simple as a passive equilibration of gasses from a culture flask, to active filtration of a gas into a bioreactor. Vent filters, whether disposable filter units or hardware with disc filters, can be useful for:

- Equilibration of gasses generated during normal cellular growth and metabolism

- Protecting aspirators, vacuum pumps and house vacuum lines from aerosols or liquid intrusion

- Filtering air/gas into equipment

- Filtering air/gas of unwanted microbes and particulates to maintain the proper environmental growth conditions in a bioreactor

- Protecting sensitive electronics from aerosol or fluid damage

- Protecting the laboratory work environment from unwanted aerosol contamination

The industry’s broadest portfolio of vent filters makes it easy to match filter performance to application requirements. These self-contained, compact filter devices provide high efficiency removal of airborne bacteria and particulates under dry or moist conditions. Rugged polypropylene housings have broad chemical compatibility.

Coming soon...

Analytical QC

Microbiology QC

Life Science Research

Try a product sample or request an equipment demonstration

Simply fill out the form and someone will be in touch with you soon.